News

VW’s “Dirty Diesels” gives life to Rivian’s future EV manufacturing plant

Nothing normal is happening at the newly acquired Rivian Automotive Factory in Normal, IL. Teslarati has discovered a massive stockpile of Volkswagen’s “dirty diesels” being stored on the aspiring electric car startup’s vast factory parking lot. The VWs on site were produced over the course of 6 years between 2009-2015, and are vehicles equipped with an emissions cheating device that became the subject of the global “VW Dieselgate scandal” which took place last year.

The owner of the plant, Rivian Automotive, is looking to make moves in the central Illinois town by developing their first production electric vehicle from the newly acquired ex-Mitsubishi factory. The company is leasing an onsite storage lot to a logistics company that’s responsible for transporting the thousands of affected vehicles to an unknown final destination.

Aerial inspections obtained via drone video by Teslarati, show an estimated 14,000 VWs being stored on the facility lots adjoining Rivian’s main factory. The plant was owned by Mitsubishi Motors until June 2016, before Rivian Automotive purchased the entire facility in January 2017 for $2 million. The facility was built in 1988 and boasts 1.9 million square feet of space, before expanding to 2.4 million square feet in 2003. Mitsubishi’s sales of the Outlander Sport (the sole vehicle produced at the factory) slumped when the Russian recession began in 2014; the vehicle was a massive hit in the country. The plant once employed 3,400 employees and ended production with 1,280 in late 2015.

“We know that the TDI emissions issue has understandably eroded the trust that we have worked so hard to build with you, our customers.” – VW in a pamphlet to affected customers

- VW Diesel vehicles being loaded off of a transport truck (Photo: Christian Prenzler for Teslarati)

- A variety of VW Diesels are being stored at the facility, some from as far as Montana [Credit: Christian Prenzler/Teslarati]

- The VWs are lined up very neatly as Vascor logistics makes use of the large lots [Credit: Christian Prenzler/Teslarati]

- Hundreds of VW 2.0 TDI’s parked awaiting their unknown future [Credit: Christian Prenzler/Teslarati]

- Hundreds of VW 2.0 TDI’s parked awaiting their unknown future [Credit: Christian Prenzler/Teslarati]

- Drone flies closely over the thousands of VW Diesel vehicles being stored at the Rivian Factory. [Photo: Jim Finch]

Images showing thousands of VW diesels on site paint a clear picture of the German automaker’s failure to come up with a real fix for vehicles equipped with emission cheating devices. VW has also been storing affected vehicles at the Pontiac Silverdome but based on our estimates, Rivian’s factory storage lots are approximately two and a half times larger than the Silverdome’s lots.

“These vehicles will be held and routinely maintained until it is determined whether an approved emissions modification becomes available. If approved, the settlement allows Volkswagen to modify affected 2.0L TDI vehicles so they can be returned to commerce or exported. Vehicles that are not modified must be responsibly recycled.” – Jeannine Ginivan, Volkswagen Group of America, Inc.

Uncertain effects from possible fixes

The vehicles stored at the site are expected to be pulled for parts and scrapped, but the company has not released official plans for all of 475,000 vehicles affected in the US as part of “Dieselgate”. VW is in the process of buying some vehicles and working towards solutions for vehicles that have been less affected by the emission devices. The 67,000 2015 3rd generation VW diesels were the first to receive an approved fix earlier this year. The fix does not bring the cars within federal compliance, but the vehicles emit significantly less NOx pollutant. VW is expected to release a phase 2 fix for the 3rd generation vehicles in 2018, which will bring the vehicles into federal compliance.

A spokesperson for Volkswagen Group of America told Teslarati that they have removed or modified more than 25% of the affected vehicles in the US, insinuating that the firm has bought back over 50,000 diesel cars since beginning the program four months ago (~67,000 were modified).

Software fixes to the 3rd generation vehicles will cause the following changes to the cars:

- Reduced performance in sport mode

- Engine sound variation

- 1-14 percent higher diesel exhaust fluid use

Owners of affected vehicles that have been given an approved fix also received two-thirds of the restitution cash that the company is issuing to customers. The last third will be distributed to owners after the phase 2 hardware update is completed. The phase 2 modifications are not designed to cause major differences in consumption or acceleration, but the cars efficiency and driving characteristics may change. Recently, The Daily Mail has reported that fixes to UK cars have resulted in “poor fuel consumption, weak acceleration, and mysterious rattles”.

Aerial Imagery of the Rivian Automotive Plant

While the terms of the deal between Rivian and Vascor Logistics are confidential, we know that revenue from the contract is contributing to the development of Rivian’s electric vehicle lineup. The global logistics company provides significant logistical services to automotive companies, one of which is VW. Rivian took ownership of the factory in January and has received incentive deals from both the State of Illinois and local municipalities.

“We are working hard to utilize the factory leading up to our production launch.” Rivian CEO, RJ Scaringe said in a comment to Teslarati.

The factory has direct access to several nearby interstate routes and has a rail car station directly on the property. Mitsubishi shipped a large portion of its vehicles around the globe from the facility, and to this day still has an operations warehouse near their old plant that’s being used for vehicle parts storage and logistics.

As Rivian continues developing their electric vehicle lineup, the company can make use of the factory by leasing out the vehicle storage lots and generate revenue. It is unclear how many more vehicles will be stored in Normal, IL or how long the vehicles will be retained on site, but Vascor’s operations at the factory appeared to be very active. VW’s polluting diesels are now giving way to the future of the automotive industry.

Vascor Logistics & Wheelan Security did not respond to our request for comment.

Elon Musk

Tesla stock woes are ‘overblown’ considering long-term catalysts: analyst

“We believe the recent stock pullback and sales declines, while significant, are overblown considering the near-term issues impacting the company and the scope of opportunities around the corner.”

Tesla stock (NASDAQ: TSLA) has been under tremendous pressure as a result of CEO Elon Musk’s involvement in the United States Government and other factors, like tariffs and lower-than-expected delivery figures.

However, one analyst says that the concerns regarding Tesla’s short-term performance are “overblown”, considering all the things the company has in the works for the future.

Mickey Legg, an analyst for Benchmark, wrote in a note on Wednesday that much of the negative narrative that has hovered over Tesla shares for the past few months is exaggerated. Instead of looking at the near-term pullback on shares that has seen a 32 percent drop in share price since the beginning of the year, Legg is encouraging investors to look at the catalysts that lie ahead.

Legg wrote in the note to investors (via MarketWatch):

“We believe the recent stock pullback and sales declines, while significant, are overblown considering the near-term issues impacting the company and the scope of opportunities around the corner. After appreciating over 90% to a high of $488 after the Presidential election, the stock has pulled back to sub-$300 levels.”

The stock has felt immense pressure in the early portion of 2025, especially as some investors are questioning Musk’s focus on Tesla, with some arguing that his CEO role has seemingly taken a backseat to his responsibilities with the Department of Government Efficiency (DOGE).

Additionally, his capacity in the government has drawn some unwarranted criticism from some, resulting in vandalism and violence from his opposition.

However, Musk’s role with DOGE will eventually come to a close, and Legg is looking forward to that, as well as other catalysts that Tesla has announced in the past. For example, the company said it plans to launch affordable models in the first half of this year:

“Our focus is on the release of a new TSLA model in 2Q25, which in our view could turn around the recent decline in vehicle sales. Furthermore, we’re cautiously optimistic about the rollout of Tesla operated robotaxis as a paid service in Austin, TX scheduled for June. While the scope of the initial rollout is expected to be limited, we are focused on the rate of expansion of the operation both in Austin and to other cities.”

Legg finished by stating that he is under the impression that a reduced capacity in DOGE by Musk would be massive for the stock:

“Recent headlines suggest Musk could be reducing his role with the White House, and we can see political backlash diminishing as the year progresses. In our view there is significant potential for a stock rebound, and we believe the breadth of near-term opportunities outweigh headwinds.”

Tesla shares are up over 20 percent as of 3:22 p.m. on the East Coast.

News

Destroying Tesla stores partially acceptable, says nearly 40% of U.S. study’s respondents

It appears that a growing number of people are willing to justify or even applaud the idea of killing people like Elon Musk or Donald Trump.

A study from the Network Contagion Research Institute (NCRI) has revealed a rather disturbing trend in the United States. Based on the study, it appears that a growing number of people are willing to justify or even applaud the idea of killing people like Elon Musk or Donald Trump. A notable number of the study’s respondents also stated that they find it partially acceptable to destroy Tesla stores as a form of protest.

The NCRI Study

The NCRI’s study was initiated to determine people’s support for political violence. As per the organization, calls for political violence towards people like Trump and Musk are becoming increasingly normalized. The same is true for property destruction, such as the firebombing of Tesla stores and Superchargers and the vandalism of consumer vehicles.

For its study, the NCRI surveyed 1,264 U.S. residents, balanced to reflect census data on race/ethnicity, gender, age, and education. Respondents were then asked demographic information, political identity, several political and psychological scales, and questions concerning their acceptance of specific forms of political violence.

Musk, Tesla, and Trump

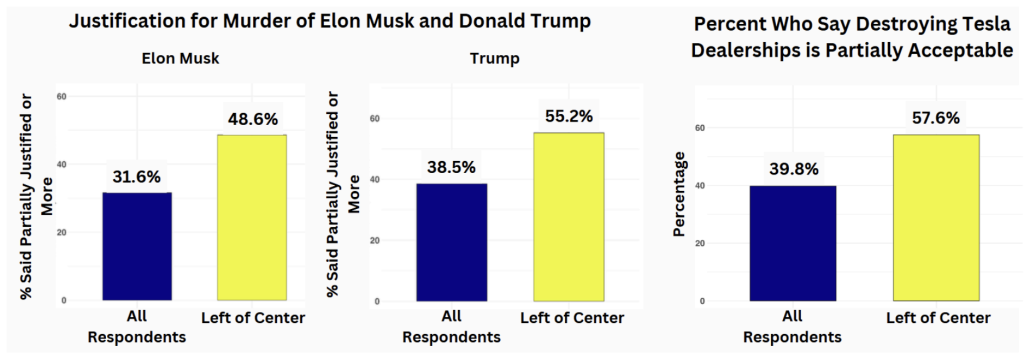

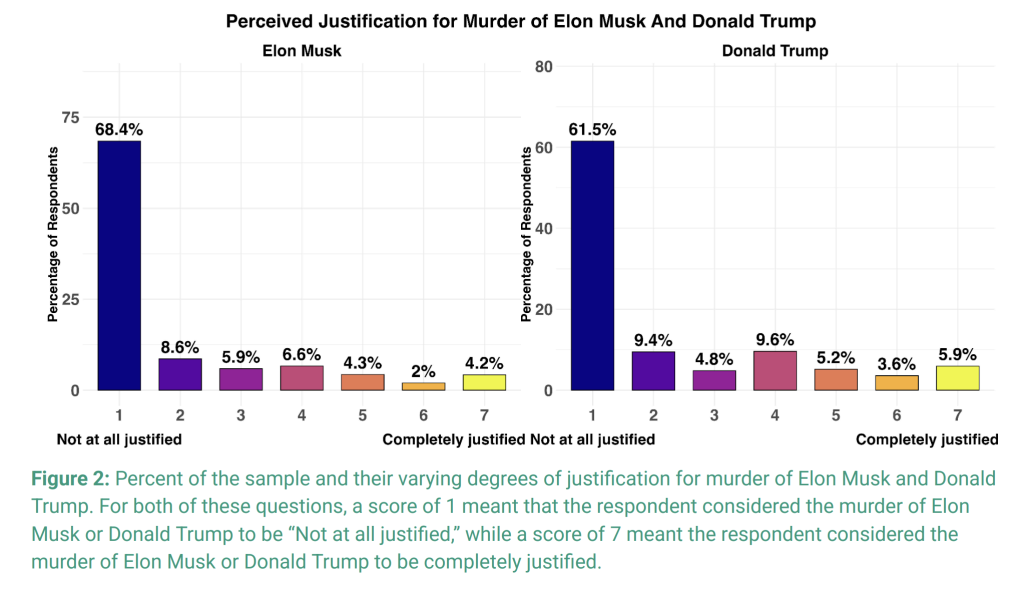

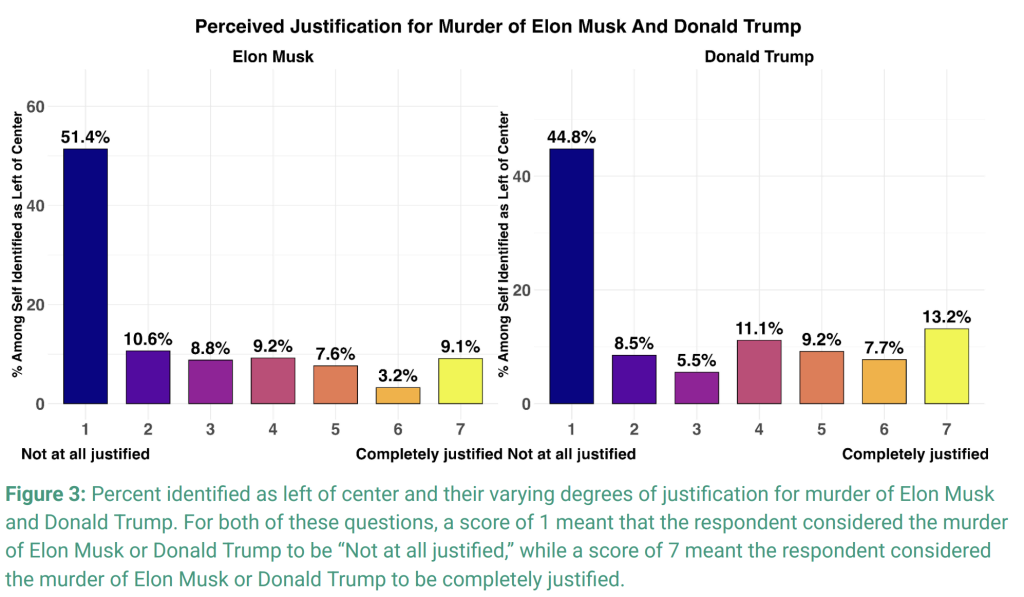

Some troubling trends emerged from the study, including the fact that 57.6% of respondents who self-identified as left of center stated that destroying Tesla dealerships is partially acceptable. Even more disturbing was the fact that 48.6% of respondents who self-identified as left of center reported that if someone murdered Elon Musk, they would at least be somewhat justified. For U.S. President Donald Trump, this number was higher at 55.2%.

Without isolating respondents who self-identified as left of center, 39.8% of the study’s respondents still stated that destroying Tesla stores is partially acceptable, 31.6% still stated that killing Elon Musk was somewhat justified, and 38.5% still stated that killing Donald Trump was somewhat justified.

What the NCRI Says

Joel Finkelstein, the lead author of the NCRI’s study, stated that an “assassination culture” of sorts is emerging, especially following the death of UnitedHealthcare CEO Brian Thompson in the hands of Luigi Mangione in December 2024. As could be seen in social media activity of people against Musk or Trump, calls for the assassination of the CEO and President are abounding among their harshest critics.

“What was formerly taboo culturally has become acceptable. We are seeing a clear shift – glorification, increased attempts, and changing norms – all converging into what we define as ‘assassination culture.’ It’s not just Luigi anymore. We’re seeing an expansion: Trump, Musk and others are now being openly discussed as legitimate targets, often cloaked in meme culture and gamified online dialogue,” Finkelstein stated.

Below is a video about the NCRI’s study.

And below is the NCRI’s study itself.

NCRI Assassination Culture Brief by Simon Alvarez on Scribd

Elon Musk

Tesla CEO Elon Musk and fmr VP candidate Tim Walz continue war of words

Elon Musk and Tim Walz continue trading barbs as the former VP candidate called the Tesla CEO a “greedy bastard.”

Tesla CEO Elon Musk and former Vice Presidential candidate Tim Walz are continuing their war of words against one another as the Minnesota politician made more comments last evening.

Musk then responded to those comments today in a post on X.

Walz said last night that Musk is a “greedy bastard” who did not pay taxes after he became successful. The former VP hopeful also said that “people like Elon Musk” should be demonized:

“Once you become successful, don’t be a greedy bastard and not pay your taxes. I don’t think we should be the party that demonizes someone because they can afford something—they worked hard & got something. We should demonize people like Elon Musk. That’s different.”

Tim Walz on Elon Musk: “Once you become successful, don’t be a greedy bastard and not pay your taxes. I don’t think we should be the party that demonizes someone because they can afford something—they worked hard & got something. We should demonize people like Elon Musk. That’s… pic.twitter.com/uq5aV2XAxT

— Sawyer Merritt (@SawyerMerritt) April 9, 2025

These comments from Walz follow previous statements he made about Tesla stock, stating that when it goes down, he gets a boost. These comments were met with criticism from people in various sectors, including Shark Tank’s Kevin O’Leary, who is nicknamed “Mr. Wonderful.”

O’Leary called Walz out for hoping Tesla shares drop as they are a holding in the Minnesota Pension Fund. Walz said the comments were just a joke.

Musk chose to respond to Walz’s comments from last night this morning in a response to the above X post, calling him “a liar”:

Tim Walz is a liar

— Elon Musk (@elonmusk) April 9, 2025

Funny enough, Musk has not avoided paying his taxes. In fact, in 2021, he paid the largest single-year tax bill in American history, as he wrote a cheque to the IRS for $11 billion:

Elon Musk’s 2021 taxes equates to over $1.5 million for every day he’s been a US citizen

It is unclear why Walz continues to speak negatively about Musk, especially as it seems he is going out of his way to do so. More than likely, it is to continue pushback against Musk’s involvement with the Trump Administration.

-

News5 days ago

News5 days agoTesla rolls out new, more affordable trim of the Model Y Juniper in U.S.

-

News1 week ago

News1 week agoTesla shares Optimus’ improved walk in new update video

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla vandal who lit Las Vegas repair center on fire arrested

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk clarifies Trump tariff effect on Tesla: “The cost impact is not trivial”

-

News2 weeks ago

News2 weeks agoTesla US Gigafactories shields from Trump’s 25% Tariffs

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoMusk says xAI has acquired X in $33 billion stock deal

-

Elon Musk7 days ago

Elon Musk7 days agoTesla Germany reports 4,935 units sold in Q1 2025

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla vehicles hit by ATV, suspect caught by Sentry Mode