Tesla Model S

Video | Tesla Motors Teardown Unveils a Tech Company

However, Tesla Motors is a different car company and wanted more control over its center stack to produce a car interior differentiator for auto consumers—a Bob Lutz essential in his car design playbook.

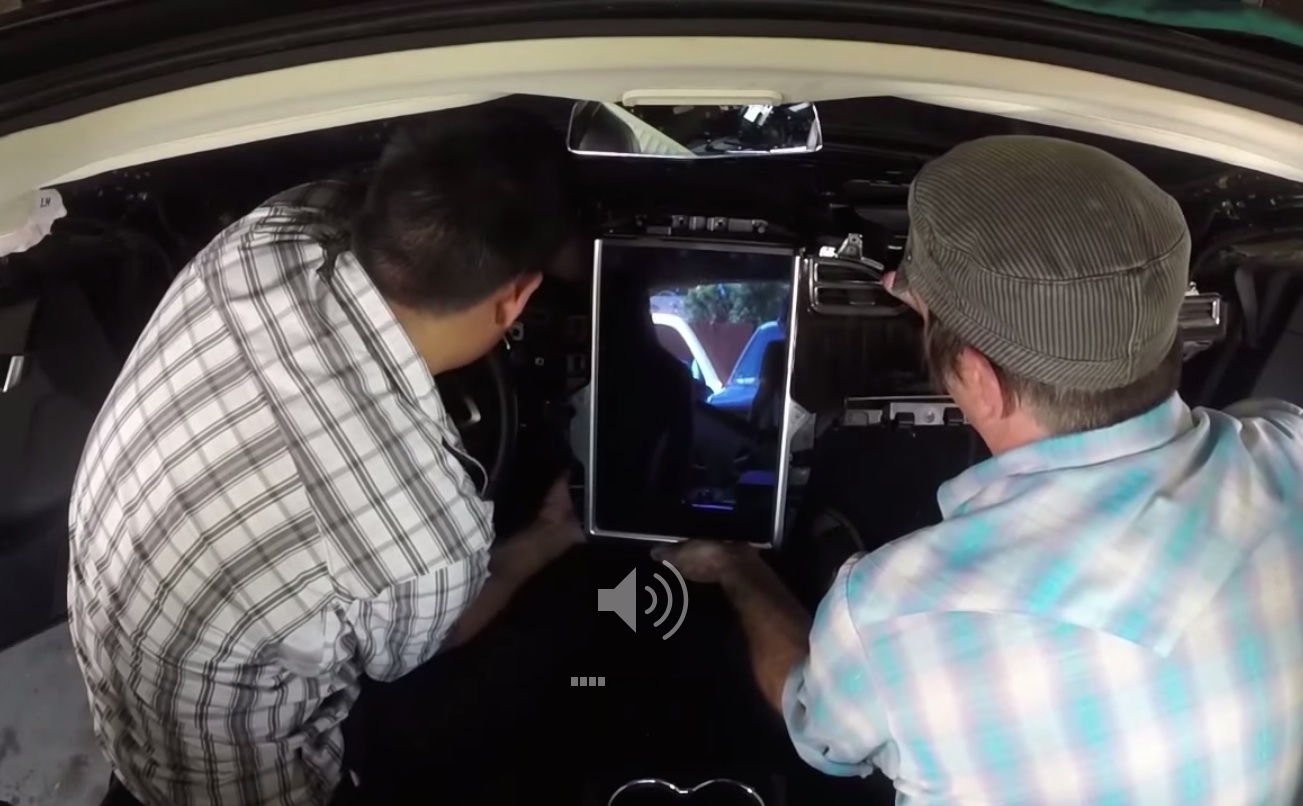

Need one word to describe Elon Musk and Tesla Motors? How about: meticulous. You see this trait in its marketing events, car design, luxury car positioning, volume levels to 11 and now the curtain has been unveiled on the electric beast’s 17-in. diagonal touchscreen control module, also known as the center stack.

Recently, Andrew Rassweiler, senior director at IHS, led a teardown of a heavily damaged Model S that contained a pristine center stack and found Tesla Motors heavily involved in the design of its gigantic head unit. Most auto OEMs will specify the parts and components of a car’s center stack but do not usually execute the design.

However, Tesla Motors is a different car company and wanted more control over its center stack to produce a car interior differentiator for auto consumers—a Bob Lutz essential in his car design playbook.

In this video interview (about 10 minutes), Rassweiler names “names” (suppliers) and shines a light on why Tesla Motors is so heavily involved in the center stack design:

Key takeaways:

- Tore out 14 modules above the chassis

- Top cost drivers for cars are displays & touchscreeens

- Ten discrete printed circuit boards for the Model S

- Tesla Motors had to have control over design and supply chain to control costs

- Why design? Elon Musk sees Tesla Motors as a tech and a car company

News

Tesla Model S and X customization options begin to thin as their closure nears

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

Tesla Model S and Model X customization options are beginning to thin for the first time as the closure of the two “sentimental” vehicles nears.

We are officially seeing the first options disappear as Tesla begins to work toward ending production of the two cars and the options that are available to those vehicles specifically.

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

🚨 Tesla Model S and Model X availability is thinning, as Tesla has officially shown that the Lunar Silver color option on both vehicles is officially sold out

To be fair, Frost Blue is still available so no need to freak out pic.twitter.com/YnwsDbsFOv

— TESLARATI (@Teslarati) February 25, 2026

Tesla is making way for the Optimus humanoid robot project at the Fremont Factory, where the Model S and Model X are produced. The two cars are low-volume models and do not contribute more than a few percent to Tesla’s yearly delivery figures.

With CEO Elon Musk confirming that the Model S and Model X would officially be phased out at the end of the quarter, some of the options are being thinned out.

This is an expected move considering Tesla’s plans for the two vehicles, as it will make for an easier process of transitioning that portion of the Fremont plant to cater to Optimus manufacturing. Additionally, this is likely one of the least popular colors, and Tesla is choosing to only keep around what it is seeing routine demand for.

During the Q4 Earnings Call in January, Musk confirmed the end of the Model S and Model X:

“It is time to bring the Model S and Model X programs to an end with an honorable discharge. It is time to bring the S/X programs to an end. It’s part of our overall shift to an autonomous future.”

Fremont will now build one million Optimus units per year as production is ramped.

News

Tesla brings closure to flagship ‘sentimental’ models, Musk confirms

Tesla is bringing closure to its flagship Model S and Model X vehicles, which CEO Elon Musk said several years ago were only produced for “sentimental reasons.”

The Model S and Model X have been light contributors to Tesla’s delivery growth over the past few years, commonly contributing only a few percentage points toward the over 1.7 million cars the company has handed over to customers annually since 2022.

However, the Model S and Model X have remained in production because of their high-end performance and flagship status; they are truly two vehicles that are premium offerings and do not hold major weight toward Tesla’s future goals.

On Wednesday, during the Q4 2025 Earnings Call, Musk confirmed that Tesla would bring closure to the two models, ending their production and making way for the manufacturing efforts of the Optimus robot:

“It is time to bring the Model S and Model X programs to an end with an honorable discharge. It is time to bring the S/X programs to an end. It’s part of our overall shift to an autonomous future.”

Musk said the production lines that Tesla has for the Model S and Model X at the Fremont Factory in Northern California will be transitioned to Optimus production lines that will produce one million units per year.

Tesla Fremont Factory celebrates 15 years of electric vehicle production

Tesla will continue to service Model S and Model X vehicles, but it will officially stop deliveries of the cars in Q2, as inventory will be liquidated. When they’re gone, they’re gone.

BREAKING: Tesla will wind down Model S and Model X production next quarter, Elon Musk confirms.

“It is time to bring the Model S and Model X programs to an end with an honorable discharge.” pic.twitter.com/Czn7aQjJE1

— TESLARATI (@Teslarati) January 28, 2026

Tesla has been making moves to sunset the two vehicles for the better part of one year. Last July, it stopped taking any custom orders for vehicles in Europe, essentially pushing the idea that the program was coming to a close soon.

Musk said back in 2019:

“I mean, they’re very expensive, made in low volume. To be totally frank, we’re continuing to make them more for sentimental reasons than anything else. They’re really of minor importance to the future.”

That point is more relevant than ever as Tesla is ending the production of the cars to make way for Optimus, which will likely be Tesla’s biggest product in the coming years.

Musk added during the Earnings Call on Wednesday that he believes Optimus will be a major needle-mover of the United States’ GDP, as it will increase productivity and enable universal high income for humans.

News

Tesla shocks with latest Robotaxi testing move

Why Tesla has chosen to use a couple of Model S units must have a reason; the company is calculated in its engineering and data collection efforts, so this is definitely more than “we just felt like giving our drivers a change of scenery.”

Tesla Model S vehicles were spotted performing validation testing with LiDAR rigs in California today, a pretty big switch-up compared to what we are used to seeing on the roads.

Tesla utilizes the Model Y crossover for its Robotaxi fleet. It is adequately sized, the most popular vehicle in its lineup, and is suitable for a wide variety of applications. It provides enough luxury for a single rider, but enough room for several passengers, if needed.

However, the testing has seemingly expanded to one of Tesla’s premium flagship offerings, as the Model S was spotted with the validation equipment that is seen entirely with Model Y vehicles. We have written several articles on Robotaxi testing mules being spotted across the United States, but this is a first:

🚨 Tesla is using Model S vehicles fitted with LiDAR rigs to validate FSD and Robotaxi, differing from the Model Ys that it uses typically

Those Model Y vehicles have been on the East Coast for some time. These Model S cars were spotted in California https://t.co/CN9Bw5Wma8 pic.twitter.com/UE55hx5mdd

— TESLARATI (@Teslarati) December 11, 2025

Why Tesla has chosen to use a couple of Model S units must have a reason; the company is calculated in its engineering and data collection efforts, so this is definitely more than “we just felt like giving our drivers a change of scenery.”

It seems to hint that Tesla could add a premium, more luxury offering to its Robotaxi platform eventually. Think about it: Uber has Uber Black, Lyft has Lyft Black. These vehicles and services are associated with a more premium cost as they combine luxury models with more catered transportation options.

Tesla could be testing the waters here, and it could be thinking of adding the Model S to its fleet of ride-hailing vehicles.

Reluctant to remove the Model S from its production plans completely despite its low volume contributions to the overall mission of transitioning the world to sustainable energy, the flagship sedan has always meant something. CEO Elon Musk referred to it, along with its sibling Model X, as continuing on production lines due to “sentimental reasons.”

However, its purpose might have been expanded to justify keeping it around, and why not? It is a cozy, premium offering, and it would be great for those who want a little more luxury and are willing to pay a few extra dollars.

Of course, none of this is even close to confirmed. However, it is reasonable to speculate that the Model S could be a potential addition to the Robotaxi fleet. It’s capable of all the same things the Model Y is, but with more luxuriousness, and it could be the perfect addition to the futuristic fleet.