Body Kits

Tesla Battery-Infused Carbon Fiber Body Panels?

The next generation of Teslas could see battery-infused carbon fiber body panels.

Tesla Motors and Panasonic could be employing nanotechnology to increase battery power density, reduce recharge times, and increase battery shelf life on the next generation of Tesla vehicles, but one challenge it will continue to face is determining a means to efficiently scale energy storage while keeping weight to a minimum.

RELATED: Unplugged Performance Tesla Model S Carbon Fiber Body Kit

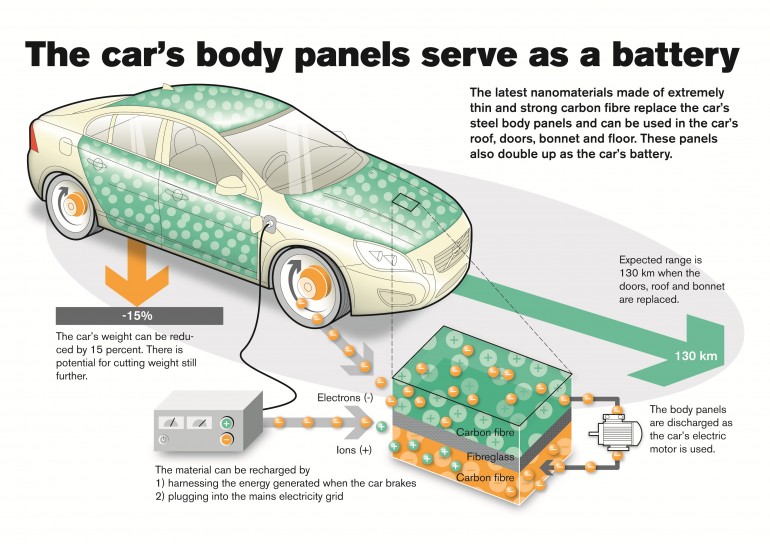

A recent unveiling by Swedish auto manufacturer, Volvo, provides a glimpse of what just may be the solution to bringing forth a lightweight and extended range electric vehicle. Volvo has spent the last few years on various electric vehicle projects, one of which they replaced the traditional steel body panels with carbon fiber composite panels infused with nano-batteries and supercapacitors.

In their experiment, Volvo replaced the hood, door panels and trunk lid on a S80 (curb weight: 3,700+ lbs) with rechargeable carbon fiber panels. Each of the carbon fiber composite panels were infused with flexible supercapacitors capable of harnessing the energy generated through regenerative braking, and discharge back into the electric motor when needed.

The combined energy that the battery panels were able to store translated to a range of nearly 80 miles (130 km) and a 15%+ weight reduction assuming a portion of the structural components were to also be replaced with this new material. If we were to apply these same metrics to a hypothetical 85kWh Model S* with proprietary Tesla battery-infused carbon fiber body panels and sub assemblies, the end result would be a vehicle with roughly a 30% increase in range and a curb weight far below the beefy 4600+lbs.

* Tesla Model S

Curb weight: 3949 lbs

Range: 345 milesHorsepower: 488 hp

Editor’s note: Numbers are purely speculative and based on many assumptions. Horsepower measurement is derived from Original Curb Weight / New Weight-to-Power Ratio

[tabs slidertype=”simple”] [tab]

Carbon fiber can provide the strength of steel

[/tab]

[tab]

Energy storage infused between layers of carbon fiber

[/tab]

[tab]

Batteries using nanotechnology infused between layers of carbon fiber

[/tab]

[tab]

Carbon fiber door infused with super capacitors

[/tab]

[tab]

[/tab]

[/tabs]

Image Source: Volvo.com

Although the bearing strength by weight of carbon fiber composites can be significantly stronger than aluminum and steel, it’s also much more brittle and provides little value in terms of energy assumption. Manufacturing quality carbon fiber goods continues to be a labor intensive and time-consuming process, thus driving price points that’s generally outside the realm of most consumers.

Body Kits

World’s fastest Tesla Model S Plaid undergoes major changes

You may have seen the formerly wrecked, then gutted 2022 Tesla Model S Plaid that had most of its body cut off and set the quarter mile record back in August, but now, it is a completely different creation dubbed the “Plaidessey.”

YouTube channel BoostedBoiz is making another major change by chopping off what little remained of the Plaid and dropping a 2001 Honda Odyssey body onto what’s left to create the “ultimate sleeper.”

In all fairness, the Odyssey body actually fits pretty well over the Model S, with less than two inches separating the wheelbase and only minor changes needed for the fenders.

One hurdle was the B pillar of the van not lining to where the Model S had its B pillar, but once the front windshield of the Model S was cut off, it made the accessibility into the car much easier.

The “Plaidessey” halfway through the changes (Credit: BoostedBoiz YouTube)

Before this major alteration, they set the Model S Plaid quarter mile world record by running 8.71 seconds down the dragstrip after cutting off the body and adding an aluminum shell to help with aerodynamics.

After setting the world record, they ran into another problem with the suspension getting stuck in low mode and even took it by a couple of Tesla dealerships in Florida to see if they could help with the issue. Unsurprisingly they weren’t able to get much help considering the changes made.

They were eventually able to enlist the help of Electrified Garage to help narrow down their issues and get a replacement part shipped out to fix the suspension.

Check out the transformation on the BoostedBoiz’s channel below!

What do you think of this creation from a 2022 Model S Plaid turned “Cyberkart” and now the “Plaidessey?”

Questions or comments? Shoot me an email at rangle@teslarati.com, or Tweet me @RDAnglePhoto.

Body Kits

Tesla Model S conversion project births stunning two-door convertible

The Tesla Model S was a subject of a conversion project at Ares’ Design, turning the flagship sedan into a stunning two-door convertible.

The Model S was Tesla’s second car behind the original Roadster from 2008. Since its original release in 2012, Tesla has made several small refinements to the car. One of the most notable is the omittance of the nosecone in favor of a new, more modern design. Tesla implemented this change in 2016, and it has been highly-accepted among the community.

Recently, rumors of a refresh to the Model S design have been circulating within the Tesla community. Because the flagship sedan and subsequent Model X vehicles have not been updated in several years, Tesla may be considering updating the design. While possibilities are endless and everyone has their opinion on what should be done, the folks at Ares Design in Modena, Italy put their own spin on the Model S, ridding it of the rear passenger doors and doing away with the top of the car.

- Credit: Ares Design

- Credit: Ares Design

- Credit: Ares Design

- Credit: Ares Design

- Credit: Ares Design

- Credit: Ares Design

The project started with the removal of the roof and central B-pillars, along with the rear doors. The wheelbase was then shortened to make the two-door design more reasonably aesthetic, and Ares designed their own doors that were fabricated to the specifications of the newly-refined Model S chassis. Structural reinforcements were added as well to ensure the safety of passengers.

Paired with interior upgrades that include new seating and a colorful new steering wheel with matching accents, the Model S from Ares is certainly one of the more interesting revisions to Tesla’s flagship sedan. However, it isn’t an ugly or unruly conversion by any means. However, some enthusiasts may have something to say about the revisions to the Model S’ design, as it was many early Tesla enthusiasts first EV.

Ares has many projects that will fit the taste of nearly every automotive enthusiast on Earth. With projects that span from Tesla to Lamborghini, there are several different routes the design studio has taken over the years to ensure the satisfaction of their customers and fans.

“At Ares, our co-create philosophy allows clients to work side by side with our designers and engineers to create their very own bespoke vehicle, a service that is unique to ARES,” CEO Dany Bahar said in a statement on the company’s website. “This Tesla project is a superb example of this; it was a pure coachbuilding project which we very much enjoy doing and seeing the results of our uncompromising standards.”

What do you think? Leave a comment down below. Got a tip? Email us at tips@teslarati.com or reach out to me at joey@teslarati.com.

Body Kits

Unplugged Performance Tesla Model 3 in Street Spec Beats Legendary McLaren F1 at Tsukuba

A Tesla Model 3 Performance with modifications from EV tuning house Unplugged Performance has achieved an elusive feat. During a run in Japan’s Tsukuba Circuit, a location famed for its twists and turns, the modified all-electric sedan managed to beat the record of a legendary naturally aspirated supercar, the McLaren F1, with an impressive lap time of 1:03.3.

What’s rather interesting is that the Model 3 Performance was actually in its street settings when it was brought to the track, and its driver was a neophyte with electric cars. While the vehicle had a slew of modifications, the Model 3 was not tuned or modified specially for the Tsukuba Circuit. It was even equipped with OEM tires from a Porsche 911 GT3 RS (997), which are good on the track but also great for regular driving.

The Model 3 that was used for the Tsukuba Circuit run was the same car that Unplugged Performance brought to the Tokyo Auto Salon. The vehicle, which belongs to Tesla owner enthusiast Erik Strait and dubbed as the Model 3 Ascension R, was brought over to Japan this January following its showcase at the SEMA 2019 show. The all-electric car was showcased in Japan as a way to demonstrate how classic tuning methods could be applied for high-performance EVs.

It should be noted that its record-breaking lap was not the first time Unplugged Performance’s Model 3 Ascension R was brought to Tsukuba Circuit. After its appearance at the Tokyo Auto Salon, the vehicle was brought to the track, where it came close to beating the McLaren F1’s lap record with a time of 1:04.7. This was just one-tenth of a second slower than the McLaren F1’s record of 1:04.6.

While the McLaren F1 is no longer the world’s fastest supercar today, the vehicle remains one of the most formidable forces of automotive engineering ever created. The car, which saw production between 1992 to 1998, was considered groundbreaking and insane at the same time. In 1998, the F1 took the title as the world’s fastest production car with a speed of 240.1 mph, and it held on to its crown until it was beaten by the Koenigsegg CCR in 2005. Even decades after its release, the McLaren F1 remains the world’s fastest naturally-aspirated production car in the industry.

For Unplugged Performance CEO Ben Shaffer, The Tesla Model 3 Ascension R is a love song of sorts to his background in JDM vehicles. It’s a fast electric car that is very capable on the track, of course, but it is also a proper road car that can be used for everyday driving.

-

News2 weeks ago

News2 weeks agoTesla aiming to produce first “legion” of Optimus robots this 2025

-

Elon Musk1 week ago

Elon Musk1 week agoTesla CEO Elon Musk’s simple message to vandals

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk confirms two measures Tesla is taking to fight vandalism

-

News1 week ago

News1 week agoTesla’s Giga Berlin director responds to anti-Musk criticism

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla owners doxxed by controversial anti-DOGE website in clear intimidation tactic

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk to file lawsuit against former US Rep Jamaal Bowman: “I’ve had enough”

-

News1 week ago

News1 week agoTesla Model Y inventory is going fast, selling out in many U.S. states

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla kicked from popular auto show as event succumbs to protest pressure