News

New aerial photos of Tesla Gigafactory 1 reveal upcoming expansion

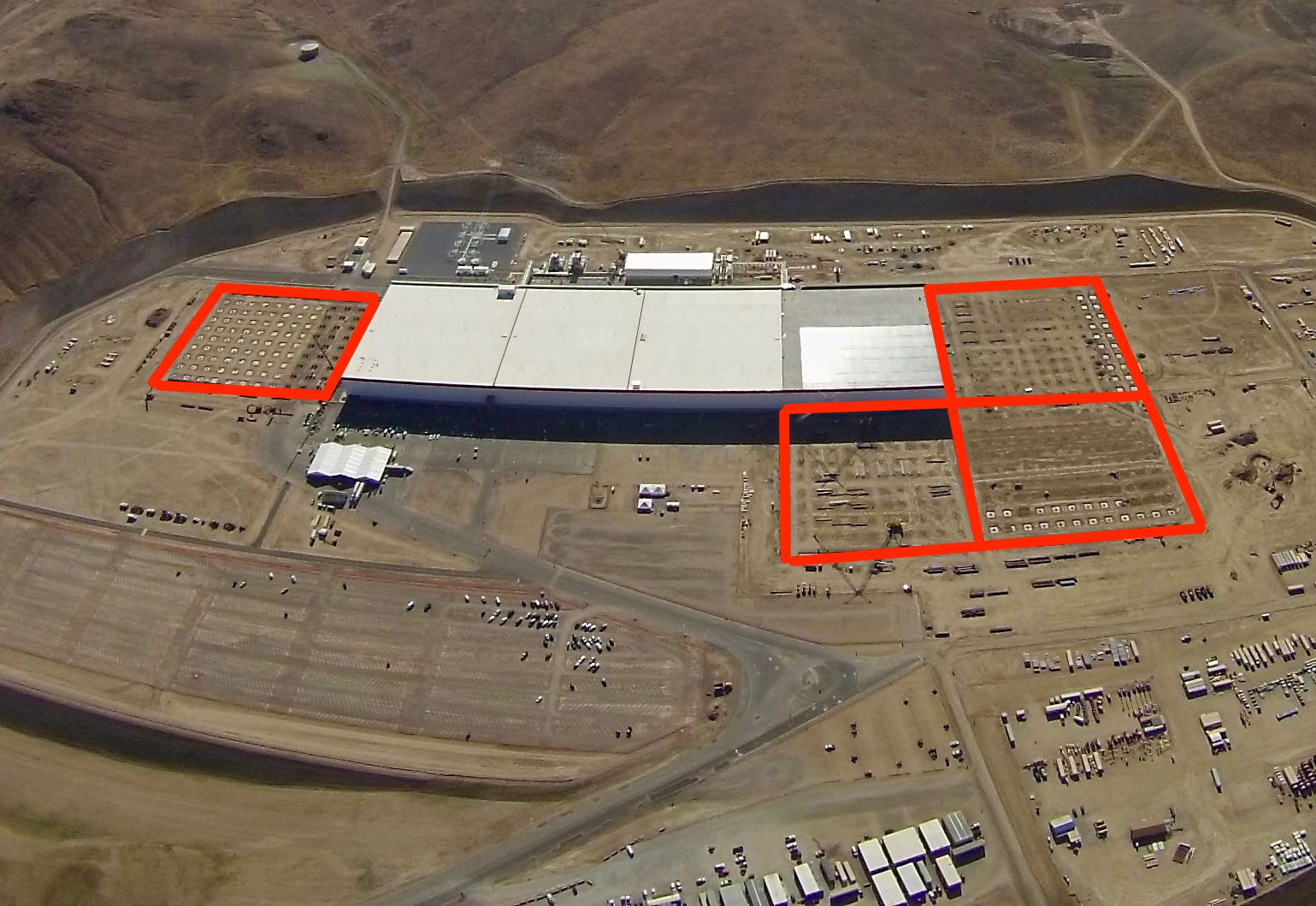

When local flight instructor Josh Mcdonald flew over Tesla Gigafactory 1 yesterday he sighted what appeared to be preparations for its upcoming grand opening party. An enormous party tent was spotted being perched outside of the battery plant. But beyond that, he also noted new footings and foundations adjoining the north and south end of the Gigafactory were being constructed. We’ve outlined these sections in red showing four new sections appearing to have the same if not larger combined footprint equal to the size of the existing Gigafactory.

The four sections seems to encompass approximately 1.9 million square feet of floor space – the size of the existing Gigafactory – representing less than one-sixth the size of the overall factory when completed. According to a report on the Wall Street Journal, the size of the construction crew has more than doubled recently and work is proceeding in double shifts, 7 days a week.

“We have to be ready with cell and pack production well ahead of vehicle production,” CTO JB Straubel, said during a walk through of the factory. “We’re accelerating our construction plans and accelerating our planned ramp up of cell production.”

Tesla wants the factory operational before the launch of the Model 3. Production for that car is now expected to begin in late 2017 with Panasonic being a major partner in the Gigafactory process. “We are running around like crazy hiring people,” says a Panasonic representative. The Japanese battery company is racing to catch up, after Elon Musk announced he was moving the timeline forward to sell 500,000 cars a year two years sooner than anticipated.

“If you look at where batteries are being made, it’s almost all in Asia,” JB Straubel says. “That was one of the big opportunities we have here, is to close the logistics loop from where cells are made and materials are made and move it closer to where our vehicles are made.”

Sam Jaffe, a principal with Cairn Energy Research Advisors, is skeptical that the reductions in battery costs that Tesla anticipates from building the Gigafactory will happen right away. “What they won’t be able to do from a battery manufacturing perspective is make the cells as cheaply as they hoped. A lot of the price reductions from the Gigafactory model come from the supply chain re-creation that they will be doing in North America. That won’t be ready by 2018.”

One thing often overlooked about Tesla is that it is a US-based company making cars in the US with US workers. It doesn’t get enough credit for its job creation prowess here at home.

Tesla will be holding a Grand Opening party this Friday July 29 at the Gigafactory. Aerial photos reveal a newly painted parking lot large enough to accommodate 2,000 vehicles and possibly a test track around the perimeter of the facility.

Elon Musk

Tesla confirms rollout of critical feature, but Cybertruck misses out

Tesla’s S3XY lineup will get the Adaptive Headlights, but Cybertruck will not.

Tesla has confirmed the rollout of a new, critical feature that is coming to the United States for the first time.

However, the Cybertruck will unfortunately miss out on it.

Tesla has a distinct advantage among many automakers as their Over-the-Air updates make their vehicles better over time. While many automakers have the ability to roll out new features through these updates, Tesla has been shown to be one of the companies that can truly make things significantly better with their cars.

A new feature coming to the United States and now rolling out is Adaptive Headlights. This feature will be applied to Model S, Model 3, Model X, and Model Y vehicles with the proper hardware.

Adaptive Headlights are different than your typical auto highbeams in the way that they can dim certain pixels of the bulb to keep visibility for the Tesla driver high, while eliminating glare for those who are in oncoming cars:

🚨 Tesla’s Adaptive Headlights dim only select pixels of the bulb to increase visibility for all drivers, while keeping brightness at a maximum for you

Perhaps one of the coolest features around

— TESLARATI (@Teslarati) April 17, 2025

For the first time, Tesla is rolling out the feature to these vehicles in the United States. European Tesla owners were able to use the function several months back, but it was pending approval in the U.S.

At first, Tesla VP of Vehicle Engineering, Lars Moravy, said that the Cybertruck would have this feature. However, in late February, he confirmed that he was incorrect and the all-electric pickup will not have the ability to get Adaptive Headlights, as the company could not fit the correct hardware in the Cybertruck’s module:

@wmorrill3 is right – I was a little overzealous and my memory failed. S/X/3/Y have it – but those thin little headlight modules in CT, just couldn’t get it in there.

— Lars (@larsmoravy) February 28, 2025

The feature certainly makes visibility better for everyone on the road and will improve overall safety while eliminating the pesky and annoying feeling of being blinded by high beams.

The Adaptive Headlight feature for Tesla is part of the company’s Spring Update for 2025.

Elon Musk

Tesla Model 3 wins ‘most economical EV to own’ title in new study

The Tesla Model 3 has captured another crown in a recent study showing the most cost-effective EVs

The Tesla Model 3 recently captured the title of “most economical electric vehicle to own” in a new study performed by research firm Zutobi.

Perhaps one of the biggest and most popular reasons people are switching to EVs is the cost savings. Combining home charging, lower maintenance costs, and tax credits has all enabled consumers to consider EVs as a way to save money on their daily drivers. However, there are some EVs that are more efficient and cost-effective than others.

Tesla police fleet saves nearly half a million in upkeep and repair costs

Zutobi‘s new study shows that EV cost-effectiveness comes at different levels. For example, some cars are simply better than others on a cost-per-mile basis. The study used a simple process to determine which EVs are more cost-effective than others by showing how much it would cost to drive 100 miles.

National averages for energy rates have been used to calculate the cost as they widely vary from state to state.

The Rear-Wheel Drive Tesla Model 3 was listed as the most economical vehicle in the study:

“The standard Tesla Model 3 is the most economical electric vehicle to drive in 2025. With a usable battery capacity of 57.5 kWh and a real-world range of 260 miles, it costs just $3.60 to drive 100 miles. That translates to an impressive 2,781 miles per $100 of electricity—making it the most efficient choice for EV owners nationwide.”

It had an estimated cost of just $3.60 to drive 100 miles.

The Tesla Model 3 Long Range All-Wheel Drive was second, the study showed:

“Next is the Long Range version of the Model 3, which offers extended range and dual-motor all-wheel drive. With a larger 75 kWh battery and 325 miles of range, the cost to drive 100 miles is slightly higher at $3.75, still equating to a strong 2,665 miles per $100.”

This version of the Model 3 had a price of just $3.75 to drive 100 miles.

In third, the BMW i4 eDrive35 surprised us with a cost of just $4.12 to drive 100 miles:

“Rounding out the top three is the BMW i4 eDrive35, with a 67.1 kWh battery and a real-world range of 265 miles. Drivers can expect to pay $4.12 per 100 miles, which still allows for 2,429 miles per $100—a solid choice for those seeking luxury and efficiency.”

Several other Teslas made the list as well. The Model 3 Performance ($4.34 per 100 miles) was sixth and tied with the Volkswagen ID.3 Pure, the Tesla Model S Long Range ($4.35 per 100 miles) was 8th, and the Tesla Model Y Long Range was ninth ($4.36 per 100 miles).

Elon Musk

Tesla offers new discounts on Cybertruck inventory

Tesla is knocking up to $10,550 off of Cybertruck units in inventory

Tesla is offering new discounts on Cybertruck units in inventory, giving customers a chance to snag a unit of the all-electric pickup for a slight reduction in price. Some are even coming with additional perks to make the offer even sweeter.

Tesla is now offering up to $10,550 off of Cybertruck inventory units across the United States. This is up from previous discounts of $6,000 on inventory Cybertrucks, and it will apply to 2024 model year vehicles.

Non-Foundation Series Cybertrucks are getting up to $10,550 off of their original prices, while Foundation Series pickups are getting up to $10,000 off. These are great deals and should help clear out some inventory from last year’s models.

Additionally, Foundation Series Cybertrucks purchased will receive free lifetime Supercharging, another great addition to make the deal even better than the $10,000 off.

NEWS: Tesla is now offering new Cybertruck inventory discounts in the U.S. of up to $10,550 off, up from $6,000 before.

• Non-Foundation Series (2024 model year): Up to $10,550 off

• Foundation Series (2024 model year): Up to $10,000 offAnyone who purchases a new Cybertruck… pic.twitter.com/8oGT6R2DDp

— Sawyer Merritt (@SawyerMerritt) April 17, 2025

The move comes as Tesla is still ramping Cybertruck production and is hoping to stimulate some additional demand for the vehicle, as it is holding on to these units. These are not Demo Drive units that have been driven by any number of people who were looking for a quick test drive.

Tesla launched a new configuration of the Cybertruck just last week with the Long Range Rear-Wheel-Drive, which undercuts the All-Wheel-Drive option by roughly $10,000.

Tesla released the Cybertruck RWD to make the AWD look like a deal

However, Tesla stripped the vehicle of several features, including Air Suspension, a tonneau cover, and interior features. For example, the Rear-Wheel-Drive trim of the Cybertruck has textile seats and no rear touchscreen, two things that come standard in the other trim levels.

The Cybertruck is the best-selling electric pickup in the United States, outperforming formidable competitors like the Ford F-150 Lightning and Chevrolet Silverado EV. However, Tesla is still working to get the vehicle to a lower price point that makes it more accessible to consumers, as its current pricing is a far cry from what was intended.

-

News2 weeks ago

News2 weeks agoTesla rolls out new, more affordable trim of the Model Y Juniper in U.S.

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla Germany reports 4,935 units sold in Q1 2025

-

News2 weeks ago

News2 weeks agoTesla expands Early Access Program (EAP) for early Full Self-Driving testing

-

News2 weeks ago

News2 weeks agoTesla celebrates key milestone for 4680 battery cell production cost

-

News2 weeks ago

News2 weeks agoElon Musk will continue as DOGE adviser: VP Vance

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoNeuralink’s Patient Registry is now open globally

-

Investor's Corner2 weeks ago

Investor's Corner2 weeks ago“Nothing Magnificent about Tesla (TSLA),” claims Jim Cramer

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoThis Tesla vandal caused thousands in damage, but she was let off the hook: Here’s why